Textile Industry and the Role of Enzymes

Enzymes, by replacing harsh chemical methods, have introduced an innovative transformation in the textile industry. It will reduce water and energy consumption while improving fabric quality, softness, and brightness, paving the way for green and sustainable textiles.

Biodesizing with Amylase

In the weaving process, yarns are treated with starch sizing to enhance their strength and reduce breakage. However, prior to dyeing and finishing, this layer must be thoroughly removed. The application of the alpha-amylase enzyme in desizing offers an efficient and environmentally friendly solution, as it hydrolyzes starch molecules into soluble sugars that can be easily washed away with water.

Key benefits of enzymatic desizing:

- Complete and uniform removal of size without fiber damage

- Reduced use of hot water and harsh chemicals

- Improved dyeing performance and color uniformity

- Savings in production time and cost

- Safer working environment for operators

Therefore, alpha-amylase is recognized as a key tool for green and sustainable desizing in the textile industry.

BONAMYL is a desizing enzyme produced by Bioluence Company, available in three grades with different performance levels depending on application conditions:

- BONAMYL HS Concentrated

- BONAMYL TX 60K

BONAMYL TX 30K

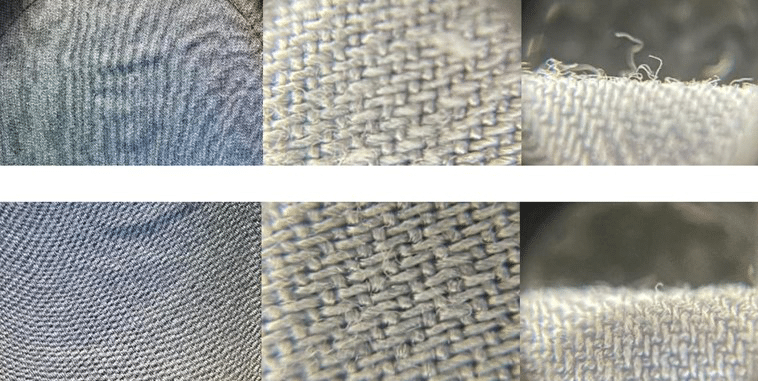

Biopolishing with Cellulase

One of the main challenges in cotton fabrics, especially in bio-stoning process, is the formation of fuzz and surface roughness after washing. Cellulase enzymes hydrolyze the surface cellulose fibers and removing fuzz has a result in a smooth, lustrous, and soft fabric

Key benefits of enzymatic biopolishing:

- Reduced fuzz and improved fabric appearance

- Enhanced softness and smooth handle

- Increased brightness and long-term color retention

- Improved durability and final product quality

- Safer working conditions for operators

For these reasons, cellulase is considered one of the most widely used enzymes in textile finishing, playing a vital role in the production of modern, high-quality fabrics.

BONACEL AK is a biopolishing enzyme produced by Bioloyns, available in two grades depending on application needs:

- BONACEL AK Concentrated

- BONACEL TX 0.5K

Degumming of Silk with Protease

Silk fibers and some plant fibers such as hemp and flax are naturally coated with substances like sericin (gum) and pectin, which cause roughness, dullness, and reduced quality. The purpose of degumming is to remove these impurities and reveal the natural luster of the fiber.

Enzymes such as pectinase and protease selectively break down sericin and protein-based compounds without damaging the main structure of the fiber, leaving it clean and soft.

Key benefits of enzymatic degumming:

- Increased luster and softness of silk

- Reduced consumption of caustic soda and harsh chemicals

- Improved dyeing performance and uniformity

- Lower environmental load of effluents

- Safer working environment for operators

Therefore, enzymatic degumming is recognized as an efficient, mild, and sustainable method for preparing natural fibers.

BONTEASE is a specialized protease enzyme designed for silk degumming and wool scouring.